As the supply of traditional energy sources such as oil and coal becomes increasingly tight, the field of clean energy has become a hot spot for investment and research and development. Biomass briquettes are being recognized by more and more people as a renewable, clean and environmentally friendly energy fuel.

The biomass briquetting process is a technical process that compresses loose biomass raw materials through specific mechanical processing to make biomass molded fuel with a certain shape, high density, and easy to store, transport and use.

Biomass Briquettes & Charcoal Briquettes

How to Make the Best Biomass Briquettes?

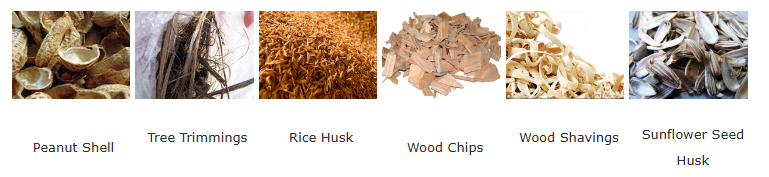

Raw materials for making biomass briquettes:

The biomass raw materials that can be used are rich in variety, widely available and renewable.

Crop straw:

Corn straw: Corn straw is rich in cellulose, hemicellulose and other components. After collection and pretreatment, it can be well pressed into blocks for biomass boiler heating or as fuel for biomass power plants.

Wheat straw: It is rich in sources and is one of the high-quality raw materials for making biomass briquettes.

Rice straw: The amount of straw left after rice harvest is also large and has a certain toughness. It can be made into biomass briquettes after drying, crushing and other treatments.

Forestry waste:

Branches: A large number of branches will be produced in the process of urban greening and forest tending. These branches can be pressed into biomass briquettes after cutting, crushing and drying, turning waste into treasure.

Herbs:

Alfalfa: Briquettes made of alfalfa have unique combustion characteristics when burned, and contain certain nutrients. They can play a role in some specific biomass energy comprehensive utilization scenarios.

Elephant grass: Elephant grass grows quickly and has high yields. Its stems and other parts can be used as raw materials for biomass briquettes.

Others

Bagasse: The sugarcane sugar industry produces a large amount of bagasse, which contains a lot of fiber components. After processing, it can be made into biomass briquettes for heating, power generation, etc.

Fruit shells: Fruit shell waste such as walnut shells and peanut shells are hard in texture. After crushing, they can be made into biomass briquettes. This type of fruit shell biomass briquettes often have good firepower continuity when burning and are often used as fuel for small biomass stoves.

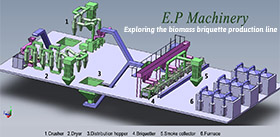

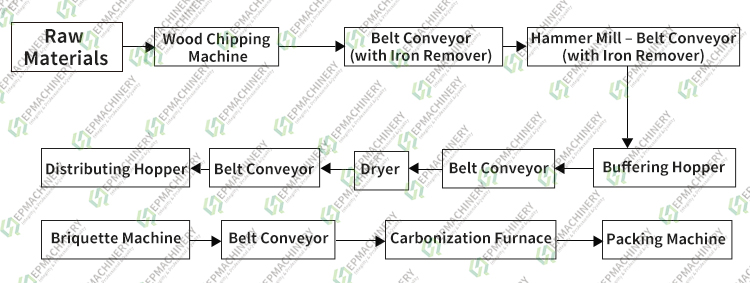

Flowchart of the Biomass Briquetting Plant:

Four Major Technical Difficulties in Biomass Briquetting & Carbonizing

Biomass Briquetting Plant Flow Chart:

Details of Biomass Briquetting Process

▌Crusher

For common corn stover, it is usually crushed to about 5-10 mm; wood chips may be crushed to about 3-8 mm

▌dry:

Many biomass raw materials have high moisture content and need to be dried to reduce the moisture content. Commonly used machines for drying biomass are: hot air dryer and drum dryer;

Generally, the moisture content should be controlled at around 10% - 20%.

▌Biomass Briquetting Machine

The processed biomass raw materials are sent to the briquetting machine through conveyor belts and other conveying equipment.

Our screw biomass briquetting machine has an automatic temperature control system and is equipped with a fully automatic length control and cutting system to compress the biomass material under high temperature (300°C-350°C) and high pressure into solid briquettes with a certain shape (hollow hexagon or hollow square) and high density.

▌Package

We will provide different packaging solutions according to your specific needs for biomass pellets or charcoal pellets.